Premium GB Hydraulic Mini Digger Breaker for 1-5.5 Ton Excavators: Top Performance & Fast Delivery

Introducing Our Premium Range of GB Hydraulic Mini Digger Breaker: Power, Precision, and Durability!

In search of the perfect mini digger breaker for your construction or demolition projects? We are excited to offer a top-quality range of GB hydraulic breakers specifically designed for mini diggers, ensuring powerful and precise results.

Our collection of GB mini digger breakers is compatible with excavators ranging from 1 ton to 5.5 ton, providing a versatile solution for a wide range of applications.

Why Choose Our GB Mini Digger Breakers?

- High-Performance: Expertly crafted with advanced technology, our mini digger breakers deliver exceptional impact energy for efficient breaking, enabling you to get the job done quickly and effectively.

- Fast Lead Times: With all mini digger breaker models in stock, we ensure prompt delivery, so you can start your project without delay.

- One-Year Warranty: We stand behind our GB mini digger breakers, offering a comprehensive one-year warranty for your peace of mind.

- Comprehensive Package: Each mini digger breaker comes complete with a hitch bracket, hoses, and two tools (chisel and moil point), providing everything you need to get started right away.

Upgrade your excavator attachments with our high-quality GB mini digger breakers and experience the difference in power, precision, and durability.

Don’t miss out on our competitive prices and fast lead times. Place your order today and watch your business thrive with the superior performance of our mini digger breakers.

Get in touch with us now to find the ideal GB mini digger breaker for your excavator and elevate your project’s efficiency with our top-notch excavator attachments.

GB Hydraulic Mini Digger Breaker

Our range of hydraulic breakers for excavators

- Korean Built

- 1 Year Manufacturer Warranty

- 2 Tools (Chisel + Moil)

- Hitch Bracket (manufactured to suit your excavator)

- Hoses and Couplers

- Ready to Work

- Quick Lead Times

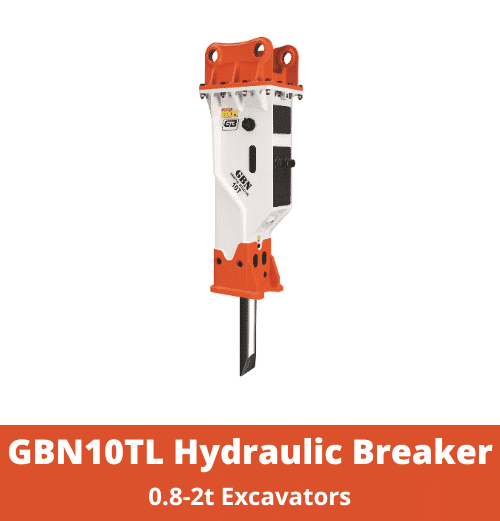

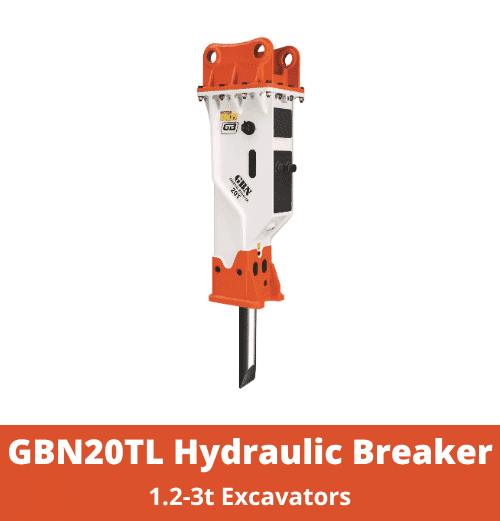

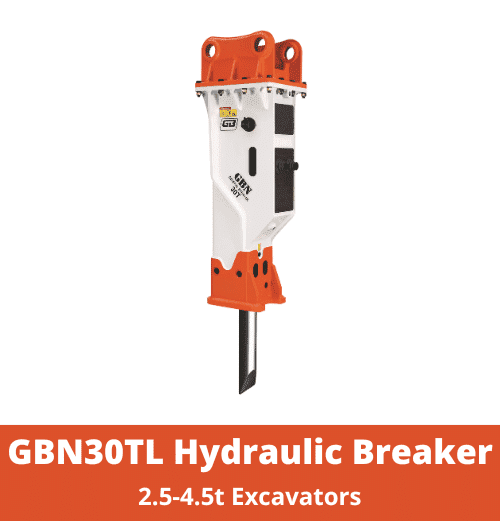

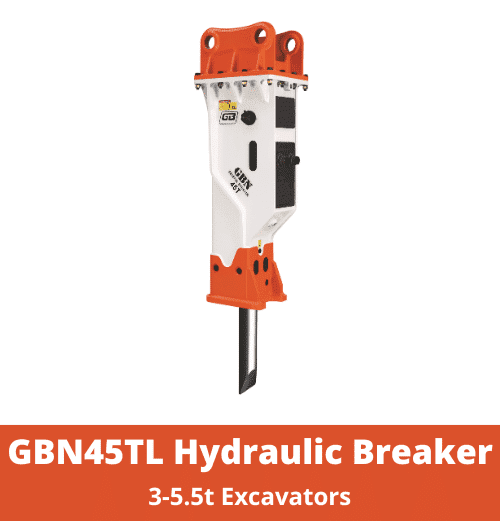

| GBN SERIES | GBN10T | GBN20T | GBN30T | GBN45T | GBN60T | GBN70T | GBN100T | GBN140T | GBN170T | |

|---|---|---|---|---|---|---|---|---|---|---|

| Operating Weight | (kg) | 135 | 145 | 180 | 250 | 310 | 380 | 570 | 890 | 1,200 |

| Tool (Moil Type) | (mm) | 40 | 45 | 53 | 60 | 70 | 75 | 90 | 100 | 125 |

| Operating Pressure (Breaker) | (bar) | 80~100 | 80~100 | 90~120 | 100~130 | 95~130 | 100~140 | 130~160 | 150~170 | 150~170 |

| Setting Pressure (Machine) | (bar) | 150 | 150 | 150 | 160 | 170 | 180 | 190 | 200 | 200 |

| Impact Rate | (bpm) | 800~1,400 | 700~1,200 | 600~1,100 | 500~1,000 | 450~1,000 | 475~950 | 480~850 | 450~780 | 420~730 |

| Accumulator Pressure (N2-Gas) | (bar/psi) | n/a | n/a | n/a | n/a | n/a | n/a | n/a | n/a | n/a |

| Back Head Pressure (N2-Gas) | (bar/psi) | 14/203 | 14/203 | 16/232 | 16/232 | 16/232 | 16/232 | 16/232 | 16/232 | 16/232 |

| Required Oil Flow | (lpm) | 15~30 | 20~35 | 25~50 | 30~60 | 34~60 | 40~80 | 45~85 | 85~110 | 100~120 |

| Suitable Excavator | Min (t) | 0.8 | 1.2 | 2.5 | 3 | 3.5 | 6 | 6 | 10 | 15 |

| Max (t) | 2.5 | 3 | 4.5 | 5.5 | 7 | 9 | 13 | 17 | 20 | |

| Suitable (t) | 1 | 2 | 3 | 5 | 6 | 7 | 10 | 14 | 17 | |

Back Head

Larger gas chamber design brings the high impact power.

Cylinder

Optimized cylinder groove design and unique balance and ratio improve anti heating of oil temperature and make stable operation possible and reduce the damages like scratches.

Through Bolts

High level of raw material adopting on through bolts to improve durability and help better supporting whole hammer body structure in stable.

Housing

Optimized housing design by 3D modeling and lower side is reinforced by high abrasion-resistant steel.

Piston

Excellent durability and special heat-treatment technology. Higher impact power with extended piston stroke.

Valve

Low-resistance reduces the hydraulic fluid temperatures which increase the efficiency. Korean built, quality hydraulic hammer

Tool Retainer

Long tool pin protects the front head from blank firing and has a long life. Dual tool retainer pins ensures correct tool alignment and dispersion of tool wear. (GBN100T above)

Wearing Plates and Buffers

Absorbs vibration to prevent impulses between carrier and hammer, also increasing durability of hammer housing and spare parts’ life time.