Needing some more information? Please take a look at our FAQ’S and hopefully they will answer your questions, if not please do get in touch with us.

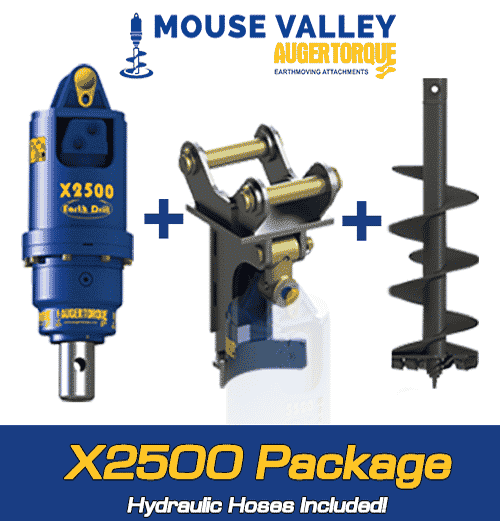

I would like to order an auger or log splitter package, what do you get with the package and do I need to supply anything?

All Auger Torque drive units are supplied with hydraulic hoses, all you require would be quick release couplers. We do not include these as standard due to the wide variety of styles and sizes available. We do stock some standard sizes, available here. If you need some assistance with this, please do not hesitate to Contact Us with pictures and dimensions of the couplers that are fitted on your excavator/machine.

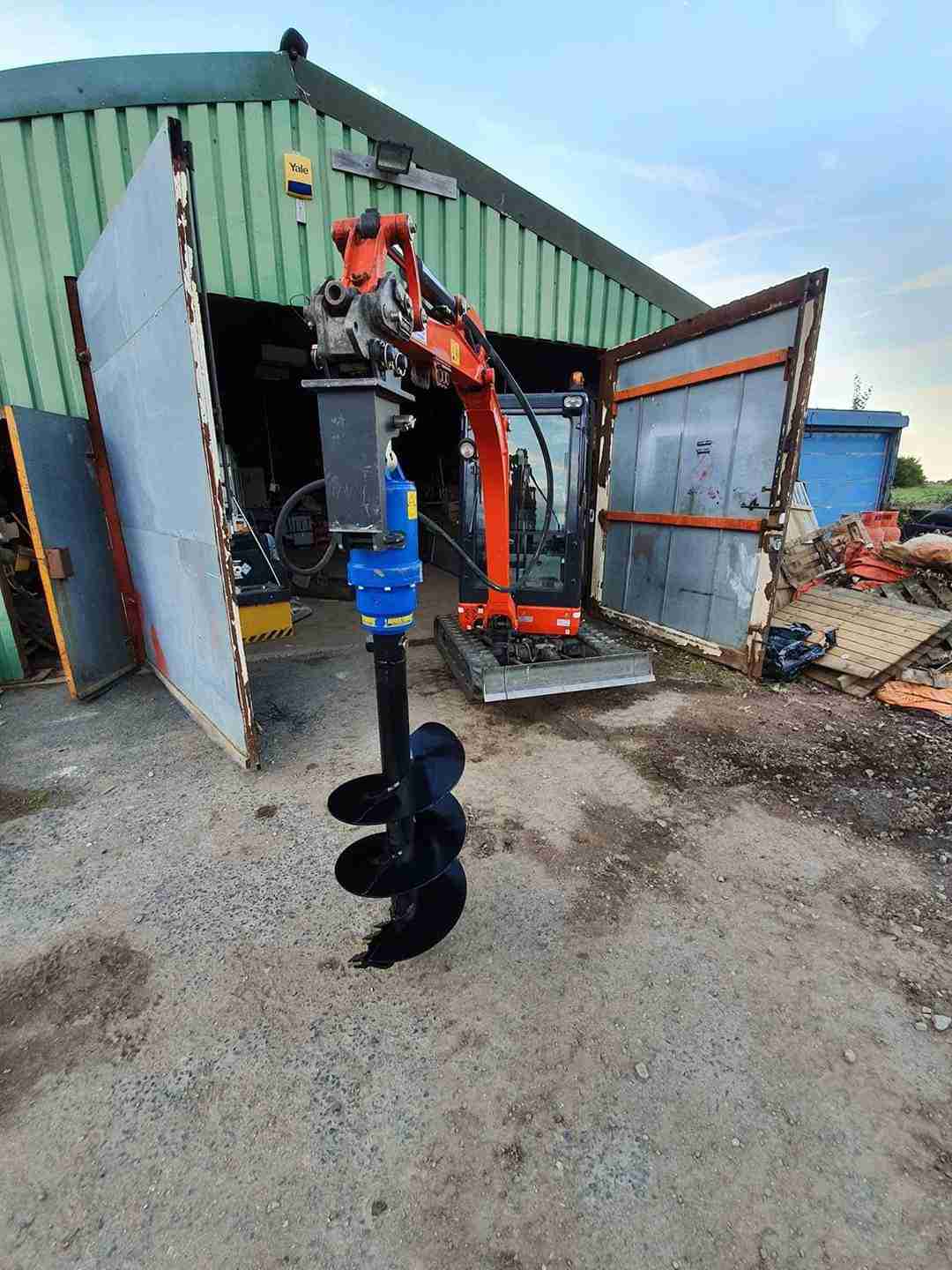

How do you put the unit on my machine/excavator?

We stock a wide variety of hitch and mounting options as standard to suit most excavators, skidsteers and mini loaders. We have the ability to design and fabricate custom mounting options, when required, to suit tractor front loaders etc. You can view our range of standard auger mounts and hitches here. If you do not see an option that works for your requirements, please do not hesitate to Contact Us with your request.

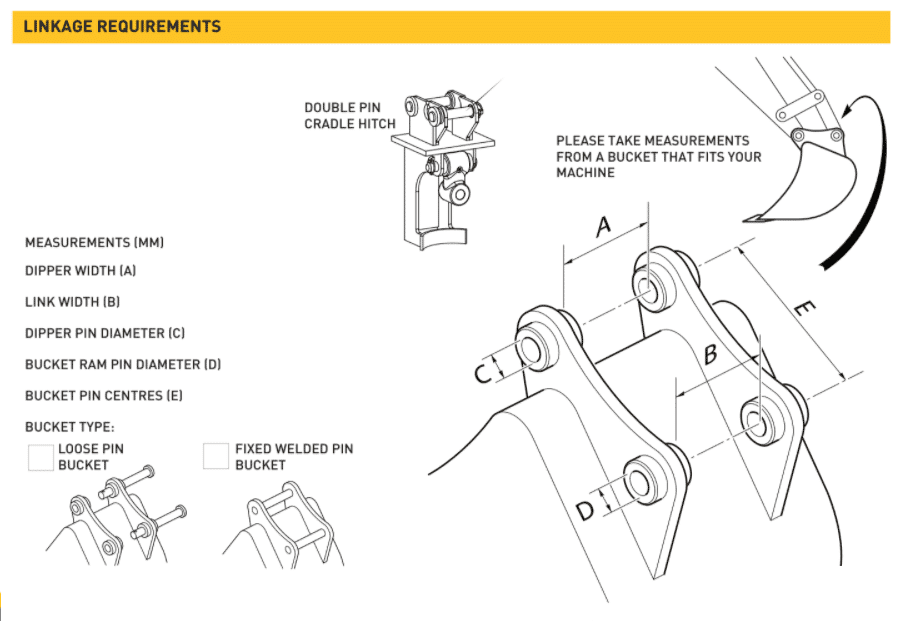

Which hitch option is best?

You can view our range of standard excavator mounts and hitches here, this is being updated regularly as we continue to increase our stock of standard hitches and frames. Choosing the best hitch option for your application is usually a balance between functionality and price point. Our preference, for excavator applications, is the Double Pin Cradle Hitch – this gives the operator maximum control of the drill string and earth drill and provides the best user experience, in our opinion of course!

What should I be looking out for when setting up the drive unit?

All Auger Torque drive units are supplied with a copy of the user manual, this details the specific setup instructions for your attachment. You can download a PDF copy here, if required. Generally speaking, all Earth Drills are ready to put to work once you have connected both hydraulic hoses to the unit and your machine. There is a short run-in process required, this is detailed in the user manual.

How do I know I have got the setup correct?

Ensure your unit is safely secured in the hitch/cradle and is properly mounted onto your machine/excavator. Both hydraulic hoses should be connected to your Earth Drill (it does not matter which side of the drive unit you have these on!) with the other ends connected to the auxiliary circuit on your excavator/skidsteer/mini loader etc. Please ensure all hydraulic connections are tight in order to reduce any chance of hydraulic oil leaks. At this point you will be safe to test the operation of your Earth Drill – working the auxiliary hydraulic controls in your machine should give you the ability to rotate your Auger Torque earth drill both clockwise and anti-clockwise. If this is not the case then please double check your setup against the Operators Manual. If you require some assistance, please do not hesitate to Contact Us.

How do I put the auger on the Earth Drill/Drive Unit?

This is the easy part – the hub on your auger will match the output shaft on your Earth Drill. The auger is then retained with a simple pin and clip. Changing augers is a simple job that can be carried out in less than a minute.

How deep can I drill with my Auger Torque Earth Drill?

The S4 Auger Range (X1500 – 4500MAX) are 1200mm length as standard, the S5 Auger Range (5500MAX – 8000MAX) are 1500mm as standard. We have a range of auger extensions available, if required.

Download a copy of the earth drill depth chart to see the depth capability of your Auger Torque unit.

How do I care for my unit and auger?

The maintenance schedule for our equipment is detailed within the user manual that will be provided with your Earth Drill. If required, you can download a copy of the standard Auger Torque Earth Drill operators manual here.

Are there any do’s and don’ts when setting up the unit and auger ?

Providing you have properly mounted your auger setup to the parent machine and connected all hydraulic fittings as per page 24 of the Operators Manual then your unit should be ready to carry out the “running-in” process. To carry out the “running-in” procedure, suspend the Earth Drill in its vertical, working position. Operate the motor for 20 minutes in each direction before application of full operating load. Be sure to carry out the warranty registration process as detailed on the warranty card supplied with your Earth Drill to make sure you qualify for full Auger Torque warranty.